Subgrade Conditions of Permeable Pavements

The subgrade conditions and strength are expressed as a CBR or Modulus value will determine how thick the pavement must be designed in order to resist traffic loads whilst the permeability will determine the amount of water storage that the base course must provide to ensure adequate water management. There is no set-in-stone value for this; every site needs to thoroughly investigated before the pavement layer thickness can be determined.

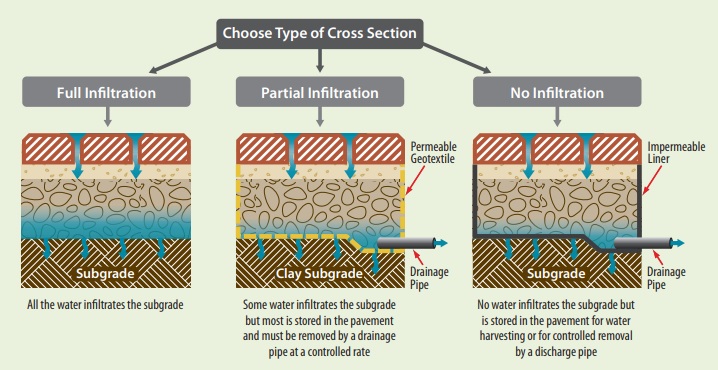

PICP can be successfully constructed over all types of subgrade not just over granular materials. The subgrade soil determines the type of pavement cross-section that is required to manage both the structural response to traffic and water management requirements. The possible cross-sections are shown schematically in Figure below

In the cases of either partial or no infiltration, the pavement’s main function is to detain the water temporarily and then to allow it to release it through a carefully sized outlet pipe to the stormwater drainage system at a rate chosen not to overload these facilities. Here, both the storage volumes of the permeable base course and bedding materials and the size of the drainage outlet must be designed together.

An important alternative use of the no infiltration cross-section is water harvesting. Here the water is retained for future reuse and only overflows are directed to the storm sewer.

a. Full Infiltration

Where the subgrade layer is formed by non-cohesive granular material it is usually possible to infiltrate all the design rainfall and allow it to flow into the subgrade and merging with the water table. Here subsurface drains are usually omitted. Some local authorities may not permit water to infiltrate the subgrade and it is only feasible on permeable gravelly or sandy soils. Essentially this is a zero discharge system as no water is discharged into traditional drainage systems and there is no need for outflow pipes to be installed.

b. Partial Infiltration

Where the permeable pavements are designed or expected to be on a clay subgrade only a small fraction of the stormwater runoff will be able to infiltrate into the soil layer; thus known as partial infiltration system. Provision must then be made to drain the water from the site using an additional drainage pipe. A filter fabric must be used to prevent clay fines contaminating the base and, if present, sub-base. Here the prime function of the pavement is temporarily to store (detain) the water that does not infiltrate the subgrade for later release to the stormwater system. The discharge rate must be designed not to overload an existing sewer or, alternatively, to minimise the size and cost of any new drainage system.

c. No Infiltration

In some cases, such as where the subgrade soil is contaminated, expansive or saline or where local regulations do not permit infiltration, an impermeable liner must be placed between the pavement and subgrade so that no infiltration is possible. Drainage pipes are required to remove the infiltrated water/liquid. Here the function of the pavement is temporarily to store (detain) all water for subsequent controlled release to the stormwater system.

This system is also adopted when water harvesting is one of the functions required of the pavement. When it is used for water harvesting the outlet pipe is directed to a sump rather than directly to the storm sewer. Water can then be pumped from the sump as required. An overflow connection from the sump to the sewer may also be needed.

Summary

Base and sub-base materials suitable for permeable pavements include unbound granular base, cement-treated base, porous lean concrete and porous asphalt. Most permeable pavements constructed to date have used open graded permeable base, sub-base or drainage layer materials developed by State or Municipal authorities for conventional pavements. The most widely used bases for permeable pavements have been unbound granular materials.

Some recent research has shown that special cement-bound mixes can offer promising alternatives to the unbound granular materials. Whilst research into permeable base materials is still ongoing; designers and specifiers are advised to check periodically with the authorizing bodies for the latest developments on permeable pavement design criteria and guidelines.