Introduction

Testing concrete while at its fresh state is not an issue at all, and even testing hardened concrete properties using test specimens such as cubes and cylinders is also not a challenging task.

However, testing a concrete structure that is already in place is totally a different trade. Normally, these test falls under two main categories, namely the destructive test and non-destructive test. As the name sounds, you would be able to figure out how the test is done.

Let’s reserve the discussion on destructive test for another article. In this article we will touch more non-destructive test, and this article in particular will elaborate more on Rebound Hammer method.

How Rebound Hammer Test is Done?

The rebound hammer test, which is also widely known as Schmidt Hammer test, is one of the most commonly used non-destructive tests for hardened concrete. Probably this is also one of the easiest methods and widely used NDT method since early 1940’s.

The detailed test guideline can be found in both American Standard as well as BS EN Standard. Under ASTM, this test is covered under ASTM C805/C805M-18 (Standard Test Method for Rebound Number of Hardened Concrete).

While under British Standards, this test is covered by BS EN 13791:2019 (Assessment of in-situ compressive strength in structures and precast concrete components)

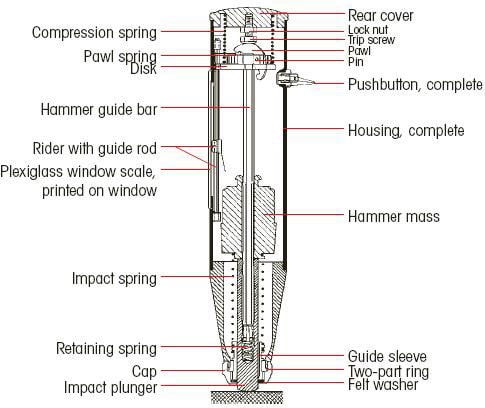

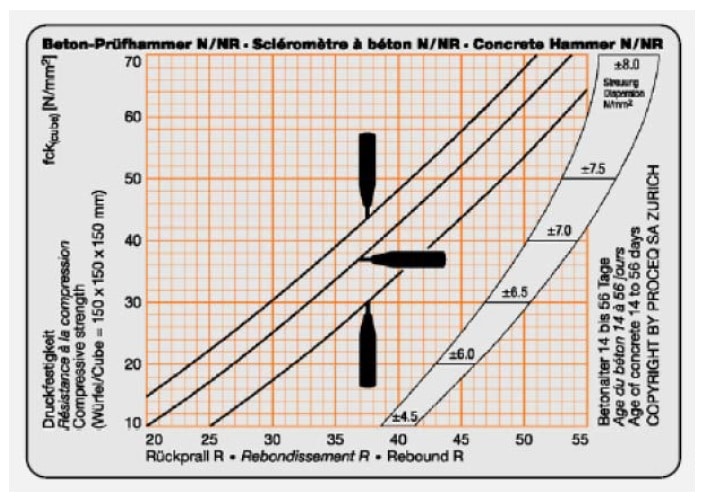

The concept of this method is to correlate the surface hardness of the concrete surface to the compressive strength of the concrete. When the Schmidt hammer is pressed against the concrete surface, the resulting rebound mass is resulted in the scale attached to the hammer.

This value is then used to estimate the strength of the concrete using the correlation graph, which is normally provided by the hammer manufacturers. However, one has to remember that the strength obtained from this test using correlation graph is only for checking purpose.

Besides strength estimation, the rebound hammer test is also widely used to check the uniformity of the concrete surface. With the value obtained from the Schmidt hammer, we can determine whether the corresponding area of the concrete has uniform amount of compaction or not. Area that is not well compacted will give lower rebound number, compared to well compacted area.

Factors that Affects Rebound Hammer Value

There are few other factors that will affect the Schmidt hammer value. Firstly, the surface condition of the test area.

As per standard requirement the test are shall be clean and smooth. Besides that the angles of the hammer when pressing on the test area also influence the rebound number.

Rebound number is also affected by voids near the concrete surface, coarse aggregate near the surface, and etc. In order to reduce the effect of these factors, it is normal practice to take average of 10 to 12 values from different points at the test area.