In urban catchments, road surfaces can account for up to 25% of solid and impermeable surfaces, thus becoming a major contributor to surface runoff. In many countries, the control and management of this runoff is the prime objective in urban planning and design. Among many other design options; the use of Permeable Interlocking Concrete Pavers has become one of the prime options. Permeable paver was first developed and introduced in Europe more than two decades ago and slowly has been adopted in many other countries since the late ’90s. Because water infiltration is actively encouraged, a wide range of environmental and cost benefits can be achieved with the use of a permeable pavement system.

The Concepts of Permeable Paving

Permeable Interlocking Concrete Paver covers a wide range of

applications ranging through landscaping, domestic paving and driveways,

public spaces, residential roads and streets and heavy duty industrial pavements

including container areas. They both carry traffic and act as a drainage facility

which can reduce or eliminate runoff, trap pollutants and harvest water for

future reuse. They combine these multiple roles with a reduction in overall

project cost by eliminating much of the drainage infra-structure such as gulleys,

sub-surface drains and sumps that is needed in conventional pavements.

Permeable pavements reduce runoff by infiltrating rainfall to the sub-grade or sub-base layers of the paveement. Provided infiltration is fast enough, runoff can be minimised or eliminated. To keep infiltration high the entire system must be designed to have high permeability. This is of particular importance in tropic countries where rainfall is often more intense than in those countries where permeable paving was originally pioneered. Some research data from Australia proves that permeable interloking pavers can be fully functional even at rainfall intensities of up to about 200 mm/hr (even after the pavements have been in service for many years).

Once water has entered the pavement sub-structure it can be drained to the

subgrade. Where this is a highly permeable granular material such as gravelly

soil, the rainfall from a typical storm can be directed to the water table. Where

the subgrade is a relatively impermeable soil such as clay this is not possible.

The function of the pavement is then temporarily to store ie detain the water

and to allow it to flow to the storm water sewers at a rate that will not overload

them. Here the only sub-surface drainage infra-structure required is an outlet

connecting to the storm sewer. In this case the pavement also acts as a

retention basin

Permeable Pavement Components

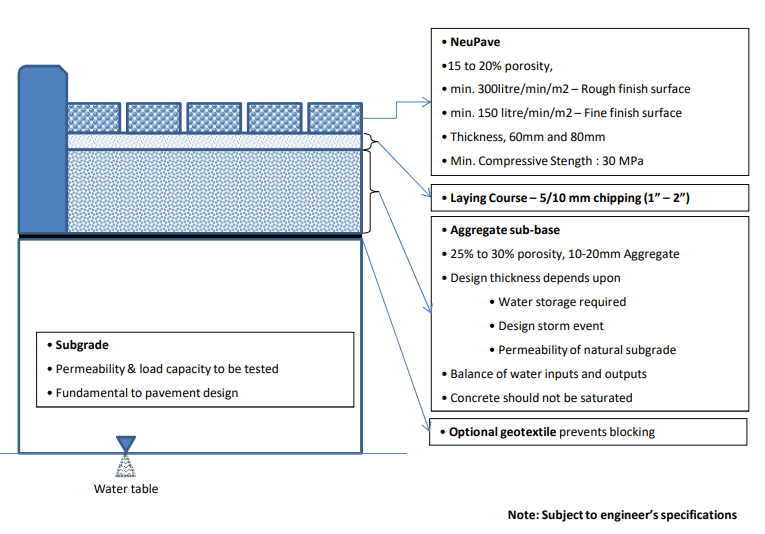

The essential components of a permeable pavement are shown in Figure 1

The elements of the pavement, which are described in detail in subsequent sections of this manual, comprise:

- A surfacing of permeable pavers design to permit the rapid infiltration of rainfall. Typically, the pavers will range in thickness between 60 and 100 mm.

- The joints between the pavers must not be left empty but should be completely filled with a uniform aggregate. Sand must not be used instead of aggregate as it slows water ingress.

- Depending on the degree of infiltration that can be achieved for a particular design storm it may be necessary to provide drainage at the perimeter of the paving to manage overflows. This can be achieved by using conventional gulley inlets to existing storm sewers or by constructing swales or bio-retention areas adjacent to the pavement.

- The permeable pavers are laid on a 30-50 mm bedding course of uniform aggregate typically 2-5 mm in size. Sand is not suitable as a bedding course and should not be used in permeable pavements because it does not allow water to infiltrate rapidly enough to cope with rainfall.

- Beneath the bedding layer, a permeable geotextile may be installed. This is optional and is only used when it is desired to mobilize biological controls of hydrocarbons etc.

- A permeable base-course normally consisting of compacted unbound granular materials provides the main load-bearing layer. The thickness of this layer must be sufficient both to resist traffic loads and to provide adequate water storage.

- On cohesive subgrades, a filter fabric must be provided under the base course to prevent the clay from migrating into the pavement. This is not needed where the subgrade is granular ie a sandy or gravelly material.

- Where the subgrade is contaminated, saline, or expansive, an impermeable membrane must be provided under the base course to prevent water from entering or leaving the pavement. This membrane will normally be run up the sides of the pavements as shown in Figure 1.

- For some pavements, a drainage pipe is installed to remove water from the pavement.

- The in-situ soil at the pavement site is known as the subgrade. The type of subgrade determines what type of permeable pavement cross-section is feasible and how thick the pavement will need to be to resist traffic and to control stormwater.

Summary

This is the first article in the series on the permeable pavement. The article has briefly discussed the basics of permeable pavement with pavers.